PRODUCT LIST

Modular Data Centers: The Rise and the Advantages

Delta Power Solutions

Product covered:

Datacetner Solutions

Motivated by the cloud computing and the application of Big Data and Internet of Things (IoT), the construction of the data center bring a new climax to the company. In such a huge market, the traditional data center is in a “solid” state which lacks flexibility and extendibility. With the development of the business and increasing applications, the drawbacks of the traditional data center have emerged gradually. It is basically built and deployed in a way of “one deployment for one project” and “one machine for one application”. The deployment goes slowly and the density is low. The server is bundled tightly with auxiliary modules such as power supply and cooling systems making it difficult to expand and one small change may affect the whole. In the end, the systems in the data center need more management software to meet the requirements in the development of the business and increasing applications. They become more redundant, and the power supply and cooling systems are barely enough to meet the requirements. It is time that we have to re-design the entire system and bring some extensions.

The modular data center is the module and compartment conducted at the location of the data center according to industry standards. The entire data center is divided into various individual areas. Each area is designed separately for its scale, power load, configuration, etc. according to a unified standard. The cooling and power supply and management systems in a modular data center are compartmentalized and modularized to make sure that they do not interfere with each other and can be operated independently without shared resources. A module can give the data center a series of advantages. “A colossal and integral data center is now out of date,” said Michelle Bailey, a trend researcher at the data center of IDC, a market research company. The modular data center has the potential to become a “virtually recognized approach” for the building of a data center in the next 5 years. Any business, regardless of its scale or the industry to which it belongs, may build a modular data center for itself and expand the scale of the data center to meet more IT-related requirements.

1. The driving force of the market to build a micro-modular data center

1.1 Announcement of multiple policies leads to the establishment of the modular data center.

The intensive announcements of national policies indicate that the government emphasizes the energy efficiency indicators and applications of new technologies in the construction of data centers. On the other hand, the excellent performance of modular data centers in the energy consumption and the advantages in the construction, planning and required space are in line with the directions of government policy. With these, the modular data centers have entered a fast-growing phase.

1.2 Equipment manufacturers promote the idea of modular data centers

The national policies attract the infrastructure and traditional UPS manufacturers to the competitive market of modular data centers. All the major manufacturers are promoting the idea of modular data centers and releasing related products. Delta Electronics and other manufacturers have solutions for the modular data centers such as the InfraSuite, which is widely accepted by users in the market.

1.3 Product advantages attract users to choose and build modular data centers

With the ever-increasing energy costs, many businesses want to ensure the usage rate of the data center and, at the same time, need to strictly control the energy costs, which is a huge burden to the operations of the business. The modular data center is more advantageous than its traditional counterparts in the civil engineering costs. It is constructed in the form of prefabrication and the designing, management and turnkey contracting costs are lower than the traditional data center by 30%. Thanks to the prefabrication, it only takes a few weeks to finish the construction, much less than the construction period of a traditional data center and a quick deployment of the data center are ensured.

Modular data centers can be expanded rapidly and installed and deployed in remote offices or for temporary tasks. When the construction and deployment is in progress, a fully-functional data center can be built after the supply of electricity, water and network connection is ensured. Hence, many customers including Internet companies, telecommunications carriers and large companies have experimentally begun to deploy modular data center solutions. For example, Internet enterprises IBM, Microsoft and Google have begun to build modular data centers. Local corporations and Internet enterprises such as Baidu, Alibaba, Tencent and related operators have used products of modular data centers in their newly built data centers. They have gained benefits in the construction period, energy consumption and cost.

2. Definitions and characteristics of modular data centers

Modular data centers are designed to deal with changes in servers such as cloud computing, virtualization, centralization and high density, improve the operation efficiency of data centers, reduce energy consumption and achieve the goal of rapid expansion and zero interference. Modular data centers are comprised of various modules with independent functions and a unified input/output interface. Modules in different compartments can make duplications for each other and a fully functional data center is established through a combination of related modules.

Modular data centers are integrated, standardized, optimized and intelligent with highly adaptable infrastructure and a computing environment of high availability.

Modular data centers will meet the urgent needs of the IT department in the future, such as standardization, module, virtual design, dynamic IT infrastructure (flexibility and high usage rate of resources), 24/7 smart operations management (process automation, smart data center), business continuity support (disaster recovery and high availability), shared IT service (inter-business and shared infrastructure, information, application), quick response to the changing needs in business (on-demand supply of resources), green data centers (energy-saving and carbon-reduction), and so on.

3. Modular data centers solve the problems that traditional data centers face

3.1 Problems that traditional data centers face

3.1.1 Long lead time of construction

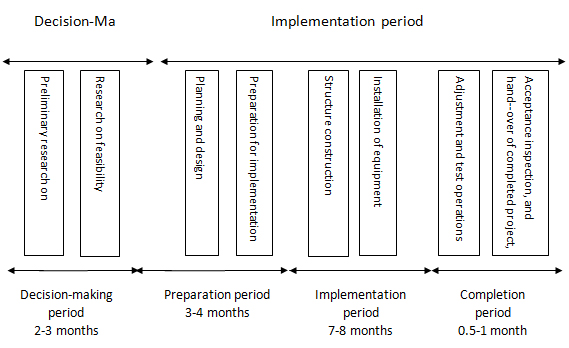

The construction period is the time needed for the planning, design and installation of the systems in the data center and its operation. As previous experience shows, the period is usually calculated in years. Fig. 1 below shows the typical schedule for the project of this type. Lots of planning processes are needed for traditional solutions, so the schedule is very lengthy. According to the actual situation in the project construction, the construction of the infrastructure is usually completed in the decision-making, preparation, implementation and completion phases. A period of about 400 days is usually needed to finish the construction.

Fig. 1. Basic construction period of data centers

- Decision-making period: This includes the preliminary research on feasibility and research on feasibility. The estimated investment is confirmed at this phase.

- Preparation period: This includes the planning, design, and preparation for construction of the data center.

- Implementation period: This includes supply of equipment for the data center, construction, installation and preparation for production. Construction and installation are a crucial part for the conversion from blueprints to physical buildings. After the preparation for construction is made, a commencement report must be submitted to the supervising department and the construction shall not be started without the corresponding approval. Preparations for production are carried out across the preparation, implementation and the completion phases. The major work will be completed during the implementation period.

- Completion period: This includes the adjustment, test operations, acceptance inspection and handover of the work.

About 400 days are usually needed for the construction of a data center. The period might be postponed when continuous prediction of the project is needed. In a time of rapidly changing business requirements, this schedule is neither suitable nor acceptable because customers wish to build a new data center only in a few months rather than a few years.

3.1.2 Poor expandability

The expandability is crucial to the adaptability of a business. System capacity is designed in consideration of the worst case scenario based on future business requirements. However, unreasonable construction may be carried out due to the inability to predict the needs over the next 3 to 4 years. Another solution is even much more worrisome because the construction is carried out conservatively only in consideration of current requirements and the capacity can be increased only at the cost of business continuity and increased operating costs. Researches show that currently the usage rate of the infrastructure capacity in a data center is less than 50%, and, in fact, only one-third of the data center is used. Think about this: the ROI of a project is supposed to be 3 times higher and two-thirds of the investment can be used for other projects of the company to create more returns.

3.1.3 High energy consumption

A huge amount of electricity is needed for the operations of a data center that has high power consumption. In the construction of traditional data centers, issues like power supply, cooling and airflow management are never taken into consideration as the first priority. The PUE(Power Usage Effectiveness) of many data centers is too high, and they usually use regular environmental power equipment of high reliability. However, the efficiency of this equipment is usually low, and the PUE of such data centers is usually more than 2.0 or higher, meaning half of the energy used for the data centers is consumed for the IT load and the other half is consumed for critical and physical internet infrastructures, such as power supply, cooling and lighting installations.

3.1.4 Difficult operations and maintenance of the data center

IT operations and maintenance face many problems. They have encountered the predicament of low service quality. The extensive operations and maintenance lead to incomprehensive resource accounts. The personnel in charge of the operations and maintenance do not fully understand all the IT resources, not to mention the management. No specialists for service interface are available and chaos occurs in both the reporting and handling of failures. IT personnel need to gather enormous data and statistical reports to find out the optimization results of the operations and maintenance systems, but routine IT operations, maintenance and management are not useful for effectively gathering these statistical data.

3.2 Advantages of modular data centers

3.2.1 Rapid deployment and shorter construction period

Modular data centers enable a shorter planning and designing period. The system structure can be configured reasonably with reference to the design target. For example, the physical arrangement of module units is made only with a selected number and type of the equipment that can meet current IT requirements. Large batch production of modules leads to off-the-shelf supply of the products and quicker delivery. Standardized connection methods reduce the workload for on-site configuration and connection to shorten the time for installation. Modules can be connected and pre-tested in the factory in the same way as the on-site work. The time needed for adjustment of the system becomes less than ever. The data center is designed to meet the current IT requirement, and only fewer small-scale infrastructures than the traditional system are needed to further shorten the time for deployment. The construction period for modular data centers is substantially shortened. Then, it takes about 7 to 8 months to build a traditional data center while 2 to 3 months are needed to build a modular data center.

3.2.2 High expendability and multiple construction phases

Since more data centers can be added to a modular architecture, one to ten modules can be constructed depending on your requirements to optimize the IT configuration in a data center. The solution of modular data centers has evidently reduced the cost during the service period of the data center. For instance, a colocation company with a large-scale IDC (Internet Data Center) is not aware of how many racks and which level of power supply a customer needs or when the customer will ask for additional business within a short period of time. The modular data center is the best choice in these circumstances.

3.2.3 Standard, stable and reliable modules

Modular data centers adopt a modular, standardized and highly-integrated design that makes the system more stable. In addition, modular data centers can provide configuration solutions such as N, N+1 and 2N to support electricity back-up depending on the customer’s requirements to reach the highest TIA-942 Tier 4 level.

3.2.4 Environmental protection and energy conservation

The cost of power during the service life of data centers occupies the largest percentage in the TCO (Total Cost of Ownership). Planning infrastructures depending on the current IT requirements and adding new modules according to the growing IT requirements enable users to provide modules only for the required equipment and the power cost saved during the service life of the data center is extremely high. The modular data center allows a good match in the capacity and workload of the power and cooling systems to improve work efficiency and reduce over-configuration. The power conversion rate of the module is 95.4%*. Adopting a standard interface and modular architecture saves electricity significantly and achieves the goal of systematic energy conservation. In-row cooling units are used to supply the air directly to the nearby hot spots. This shortens the airflow distance and improves the cooling efficiency to solve the problem of hot spots. The cold aisle containment is isolated to ensure non-interference between the cold and hot air and to prevent the heat island effect due to airflow disturbance and loss of air and refrigeration amount. Compared to traditional data centers, the cooling efficiency of a modular data center is increased by more than 12%*. The PUE drops to less than 1.5 thanks to the combination with the chilled-water and free cooling systems.

3.2.5 Intelligent management with highly-efficient operation

The intelligent management system is able to provide energy-saving and consumption-reduction to customers. It realizes multi-level refined energy consumption management of data centers and positions additional energy consumption points precisely with the support of multiple reports. Optimized energy-saving plans are generated from the Big Data analytics to build green data centers. Optimal assets management is implemented within the life cycle of the full-network assets to realize the closed-loop management of information and to ensure real-time update and management of data. It is useful for the clients to establish their assets maintenance plans that indicate the implementation of active early warning. The plans can be adjusted dynamically and optimized plans reflecting the actual situations are outputted to create the best assets management function.

4. Definition of modular products and system components

Modules are applicable to the data centers in the following two categories:

(1) Partially prefabricated data center:

The data center built by a mixture of deployed prefabricated modules (rack system, cooling system, cabling system and monitoring system) and the traditional “on-site construction” system is called “partially prefabricated data center”.

(2) Fully prefabricated data center:

A fully prefabricated data center is built with the prefabricated modules (power supply system, rack system, cooling system, cabling system, monitoring system) as a single separately enclosed space. The modules are divided into parts when transported to the site and re-assembled at the site. This data center needs the support of external infrastructures such as generators, chiller units or high-low voltage power distribution systems.

*Note: The data were evaluated by Delta GreenTech.

.gif)