Delta Two-phase Immersion Cooling

With the increasing demand for high performance computing in data centers and the continuous advancement of IT equipment process technology, high thermal design power chips require a new advanced cooling technology. Delta's two-phase immersion liquid cooling has emerged to meet these new requirements.

Integrating new technology and an innovative mechanism design, Delta's two-phase process directly immerses electronic parts and equipment in non-conductive coolant, and removes heat through the phase change of the coolant. This improves heat dissipation efficiency by reducing the heat exchange process, which is significantly more efficient than traditional air cooling, reducing energy consumption by 84%.

Integrating new technology and an innovative mechanism design, Delta's two-phase process directly immerses electronic parts and equipment in non-conductive coolant, and removes heat through the phase change of the coolant. This improves heat dissipation efficiency by reducing the heat exchange process, which is significantly more efficient than traditional air cooling, reducing energy consumption by 84%.

Features

Low PUE

< 1.08

Power Usage Effectiveness

High Cooling Capacity

100 kW

Capacity Per Tank

Reduce Cooling Power Consumption

84%

Compared to Traditional Air Cooling

Seismic Protection

GR-63 Zone 4

Richter Magnitude 8

Success

Story

Story

Place the IT equipment in Delta Two-phase Immersion Cooling system and fill it with a non-conductive liquid. The immersed IT equipment will boil the liquid due to the heat generated by the operation. Heat is taken away with the vapor generated by the boiling. The rising vapor contacts a condenser and changes back to liquid. As the vapor circulates continuously in the sealed tank it achieves the goal of high heat dissipation efficiency.

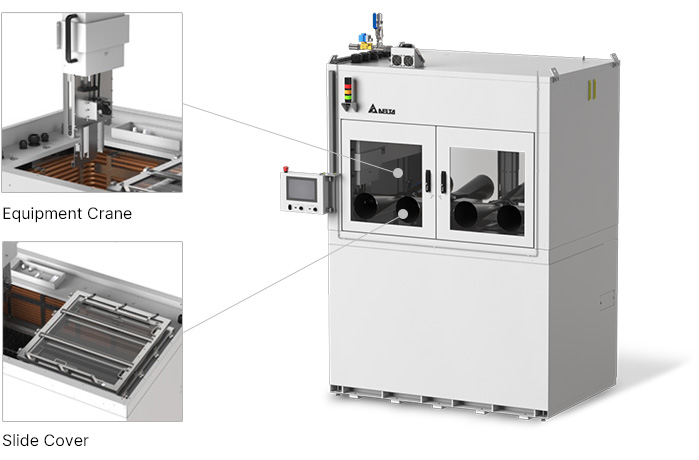

Low Emission Rate x Easy Maintenance

When IT equipment is loaded and operated in a sealed tank filled with non-conductive coolant, Delta's exclusive patented mechanism design allows the equipment to be hot swapped and replaced in a closed environment without stopping the machine.

A coolant recycle status is presented through human-machine interface, and the IT equipment can be taken out according to the instructions. The coolant can achieve the goal of an extremely low emissionrate, thereby reducing the total cost of ownership.

A coolant recycle status is presented through human-machine interface, and the IT equipment can be taken out according to the instructions. The coolant can achieve the goal of an extremely low emissionrate, thereby reducing the total cost of ownership.

Innovative Mechanism Design

Applications

Contact Us

The two-phase immersion cooling solution is a customized solution for HPC data centers and hyper-scale data centers, and is available for larger projects. For further inquiries, please contact datacenter.solution@deltaww.com.

.gif)